Price 3870000.0 आईएनआर/ टुकड़ा

Specification

- प्रॉडक्ट टाइप

- Cnc Vertical Machining Centre

- सामान्य उपयोग

- Industrial

- मटेरियल

- वजन (किग्रा)

- किलोग्राम (kg)

- ऑटोमेटिक

- पावर सोर्स

- आयाम (एल* डब्ल्यू* एच)

- मिलीमीटर (mm)

- वारंटी

- 1 Year

Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- डिलीवरी का समय

- दिन

About

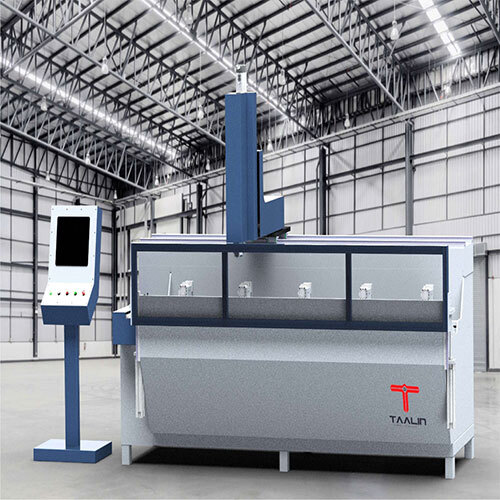

MC 4XA Profile Machining Center 4 Axis having interpolation with operation range up to 4000/5000/6000 mm working lengths, can-do high-speed routing, end High speed ATC spindle system with 11 Tool-Posts for uninterrupted machine irrespective of required tool size. User friendly part programming by TaaLCAM software with the provision for Direct DXF loading or Part programming through preloaded macros to assist all kind of hardware routings slots. Servo based control systems with planetary gear boxes ensure high precision in all applications. Operation range of up-to 5000mm in X-axis, 250mm-in Y axis and 400mm-in Z axis. Full CNC Windows Touch-Screen has the capability of remote access for quick troubleshooting from OEM to reduce the breakdown time to very minimal level. A plethora of additional features gives flexibility to operate on all kind of demanding environments.

Easy to use Industrial touch PC (IPC) as programming and user Interface along with CNC controller makes the machine IOT enabled suitable for industry standard 4.0.

.

11 Tool-Posts of ATC allows pre-loading of different kind of tools so that operations are not interrupted for changing of tools. The ATC tools are mounted on the spindle carriage allowing quick change of tools without the need for moving to any side.

It can do all kind of routing applications as per design. All new programs can be developed in the format of Macros or through TaaLCAM software with scaling up or scaling down features. TaaLCAM has the feature to accept DXF files directly for profile machining.

7 number of easy to shift Automatically adjustable pneumatic clamps (with the option for additional clamp) give higher grip in case of aluminium routing and milling applications.

End Milling Applications can be carried out precisely with the help of specially designed end milling cutter.

A Library of Pre-loaded Macros (both in Controller and TaaLCAM software) are available by default with the machine which helps in carrying out most of the contemporary hardware fixing slot routings. It has scalable features. New Macros can be develop both for controller & TaalCam

The Machine can be divided to 2 sections for loading and unloading of profiles without the need for pausing the operation. This feature allows simultaneous working of 2 or more profiles.

High Speed 7.5/9 Kw Electro Spindle is durable and accurate to carry out routing, end milling and drainage slot applications.

Ethernet protocol for high-speed communication between servo system & CNC controllers, minimises wirings while reducing cycle times.

Windows Touch-Screen IPC controller comes with enhance features of Remote Access which enables the OEM to develops application programs & carry out troubleshooting to reduce machine down time.

Large number of profile programs can be stored to avoid the requirement of re-programming.

High-Performance CNC Machining

Experience advanced automation and versatility with our 4 Axis CNC Aluminium Profile Machining Center. With automatic tool changing capability and four-axis motion, it delivers complex machining operations on aluminium profiles, enhancing productivity while ensuring consistent accuracy in every project.

Comprehensive Support and Service

Rely on our expertise as a manufacturer, service provider, and supplier in India. We provide installation, operational training, and after-sales support, backed by a one-year warranty. Our team is dedicated to ensuring seamless integration and maximum uptime for your industrial operations.

FAQs of 4 AXIS CNC ALUMINIUM PROFILE MACHINING CENTER WITH ATC:

Q: How does the 4 Axis CNC Aluminium Profile Machining Center enhance productivity?

A: The machines automatic tool changer (ATC) and advanced four-axis movement allow for efficient, uninterrupted processing of complex aluminium profiles. This automation reduces manual intervention and minimizes downtime, leading to higher output and consistent quality in industrial applications.Q: What materials can be processed with this CNC machining center?

A: Primarily engineered for aluminium profiles, this machining center is suitable for various metal materials commonly used in industrial manufacturing, offering flexibility in handling different types and grades as required by your project.Q: When should I schedule maintenance for optimal machine performance?

A: Regular preventive maintenance should be conducted as recommended in the user manual, typically every 6 to 12 months, depending on usage levels. Our after-sales team also provides scheduled maintenance services and remote support across India to keep your machine running smoothly.Q: Where can this machine be installed, considering its size and requirements?

A: Given its dimensions (2820 x 1820 x 1550 mm) and operational needs, the CNC machining center should be installed in a well-ventilated industrial space with a stable electrical supply and adequate space for service access. We offer on-site installation and setup for customers throughout India.Q: What is the general workflow or process for machining aluminium profiles with this center?

A: The process involves loading the aluminium profile into the fixture, selecting or programming the desired operation via the CNC interface, and allowing the machines four axes and ATC to perform automated, multi-step machining tasks such as cutting, drilling, and milling in a single setup.Q: How does the automatic tool changer benefit daily operations?

A: The automatic tool changer (ATC) allows for rapid and seamless switching between different machining tools, eliminating the need for manual changes and reducing machining cycle times. This feature is particularly beneficial for repetitive or multi-operation jobs.Q: What kind of warranty and support can I expect after purchasing the machine?

A: Your purchase includes a 1-year warranty covering manufacturing defects and essential components. We provide on-site support, troubleshooting, parts replacement, and training to ensure your CNC machining center delivers optimal performance throughout its warranty period and beyond.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Machining Center Category

एल्युमिनियम मशीनिंग सेंटर

माप की इकाई : यूनिट/यूनिट

सामान्य उपयोग : खिड़कियाँ और दरवाजे बनाने के लिए

न्यूनतम आदेश मात्रा : 1

वारंटी : 1 वर्ष

मूल्य की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

|

TAALIN MACHINERY & ROBOTICS PVT. LTD.

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

जांच भेजें

जांच भेजें